Pre-cooling of coolers or heat exchangers at industrial plants is the latest revolutionary system of decreasing air temperature before it enters the fans.

The problem of failure of fan motors, fan motor loads, excessive wear and tear and abnormal power consumption in difficult working conditions and high temperatures is the past.

THE PROJECT OF PRE-COOLING OF THE COOLERS BY USING THE WATER MIST SYSTEM IN THE OIL REFINERY IN PANCEVO HAS BEEN PROCLAIMED TO BE THE MOST PERSPECTIVE PROJECT IN THE ENTIRE GAZPROM NEFT COMPANY.

The system of pre-cooling of coolers reduces the temperature of the air when it comes out of the cooler with cooled air in the summer periods. Nozzles that are evenly distributed under the cooler, spray water into small droplets that, in contact with hot air, take heat and turn into water vapor, which results in cooling of air by about 10 degrees. In this way, the following benefits are obtained (concrete example in the refinery:

BENEFITS – ELECTRIC POWER

- In the design conversion, electricity consumption of is decreased for 30%

- All frequency motors with a built-in cooling system were loaded with 70%. In normal operating conditions WITHOUT the cooling system, the load level would be at its highest.

- Estimated life cycle of the equipment has been increased for 20%

- In-between maintenance periods of the electric motors (replacement of bearings, cancellations ...) is prolonged.

BENEFITS OF EXTRACTION OF WHITE DERIVATIVES:

By reducing the temperature underneath the coolers, we were able to obtain the following results:

- Possibility of increasing catalyst conversion for 20%

- Increased extraction of white derivatives for 3 tons of gasoline per day and 12 tons of diesel per day

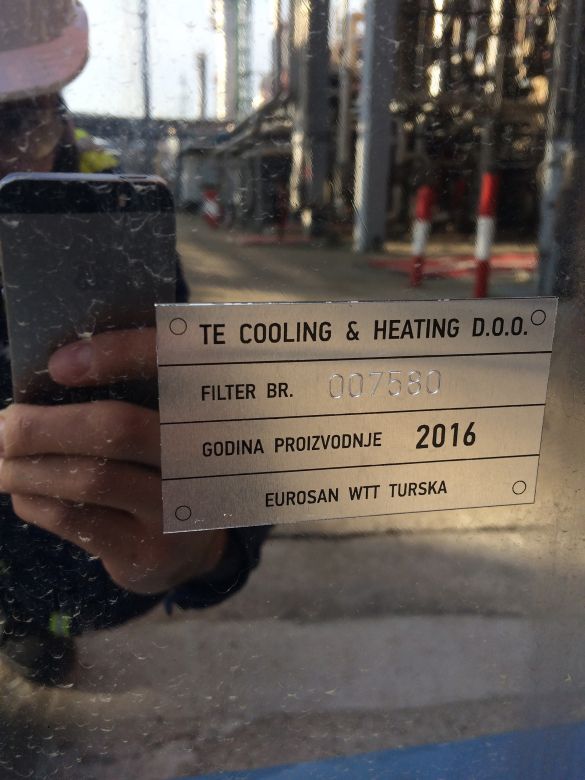

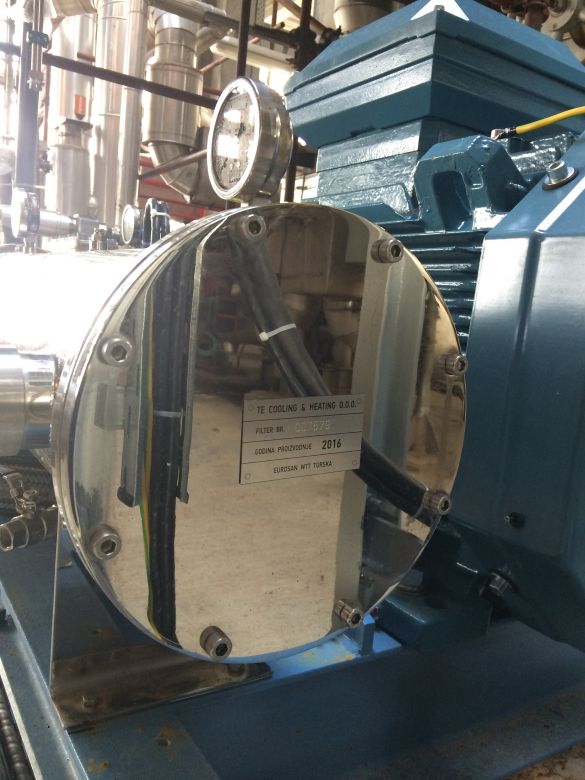

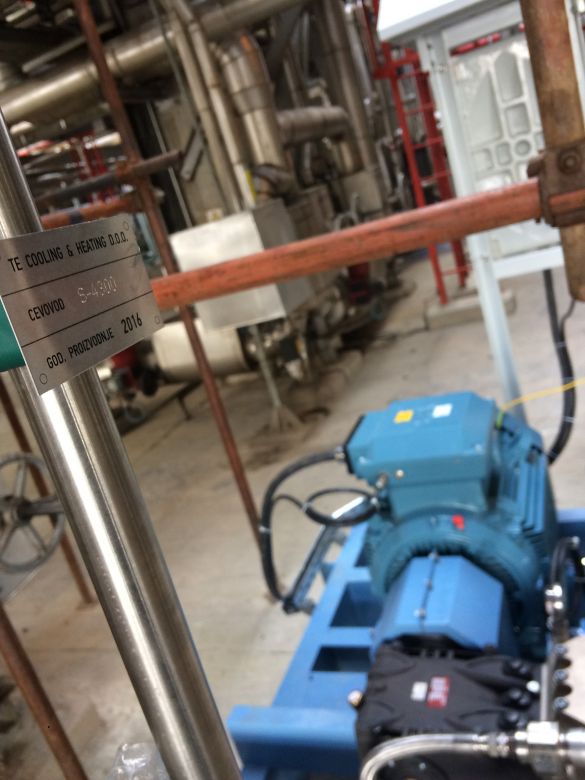

Reference