Vintners all around the suffer significant losses due to too low humidity in wine cellars. Wine losses and, of course, profit losses, can reach up to 15% in a two-year period, by evaporating through the casks due to oscillations of moisture levels. Oak casks, stored or in use, are sensitive to inadequate relative humidity and can be damaged even before use.

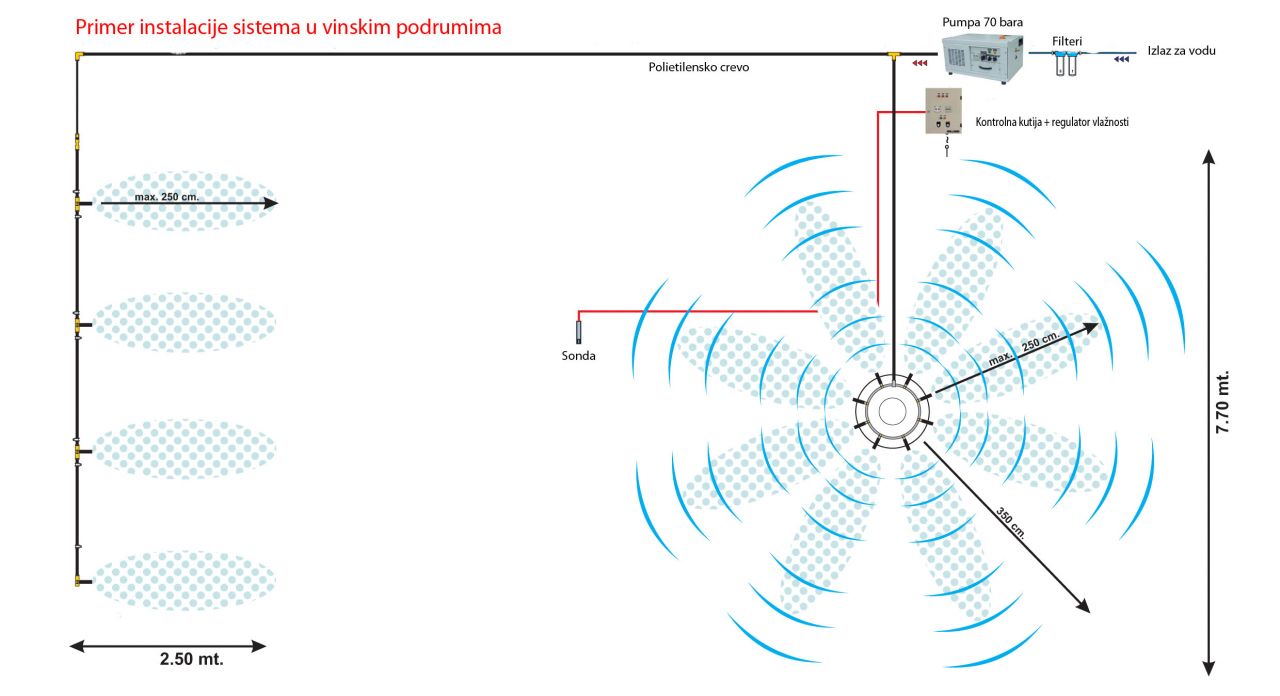

The TE cooling system is ideal for humidifying wineries and wine cellars. Adaptable to every facility, this system precisely maintains optimum air humidity. The nozzle tube is positioned along the entire space, thus allowing even distribution of moisture.

Wine cellars throughout the year, or in some periods, cannot attain the appropriate amount of moisture which can cause different problems. Low humidity is the basic factor that influences natural evaporation, causing a constant loss of quality and therefore a loss of money, not only because of the loss of time and workforce, but it also results in the fact that wine has to constantly be replenished in the casks. In addition to this, wooden casks are subject to the dehydration of their external structure which, at the same time, affects quality and efficiency.

TE cooling systems solve all these problems naturally and economically, by regulating the temperature and humidity of the air in wine cellars. Water drained by the system is converted into water vapor whose particles are less than 5 microns, which is thinner than human hair, thanks to specially patented nozzles. These fine particles of water are immediately absorbed in the air without wetting the facilities and surfaces in the room.

The results are noticeable: casks keep their efficiency for a longer period of time, they keep the quality of the wood longer, which enables excellent production and prevents evaporation of the product. This saves money that refunds the investment in our systems in just a few months.

The barrels must be positioned in places where they will be protected from draught and light. Optimal air humidity oscillates between 65% and 85%. Below 65% there is a high risk of dehydration of the barrels and over 85%, mold and yeast are created. The air humidity level in the range of 80% to 85% significantly reduces the "loss of wine".

The complete structure of the barrel depends on the level of air humidity, as this prevents the dehydration of the barrel and the opening of its joints. It is very important to avoid airflow and excessive ventilation in wine cellars. With the appropriate level of air humidity the barrier feels calm and comfortable” in the cellar.

BENEFITS

- The productivity of the wine cellar increases in general

- Constant air humidity is maintained

- The cost of labor needed to replenish the barrels is reduced

- It is economical compared to other solutions

- It eliminates the dehydration of wooden casks

- It prevents the natural evaporation of wine

- It helps maintain the proper temperature

"LOW COST" SYSTEM

Very low costs associated with our systems are a very important factor in wine cellars if compared with other air conditioning solutions. The costs of energy consumption are very low, installation is easy and fast and maintenance costs are minimal.

TOTAL CONTROL

Normist systems are equipped with a variety of electronic capabilities

to thermostats, hydrostats and timers. In this way, with these devices you can maintain the desired temperature throughout the day, regardless of the external weather conditions.

Reference

Kovačević inženjering d.o.o.

Banatski Karlovac - proizvodnja vina

Toplički vinogradi

Beoljin, Srbija - Proizvodnja vina

Recommended products